Melting Point Trends 2025: A Comprehensive Look at the Future of Materials Science

Melting Point Trends 2025: A Comprehensive Look at the Future of Materials Science

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to Melting Point Trends 2025: A Comprehensive Look at the Future of Materials Science. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Melting Point Trends 2025: A Comprehensive Look at the Future of Materials Science

The world of materials science is constantly evolving, driven by advancements in research and technological innovation. One key aspect of material characterization is the melting point, a crucial property influencing a material’s applications and behavior. As we approach 2025, understanding the trends in melting point research and development is essential for various industries, from manufacturing to energy production.

This article delves into the anticipated melting point trends in 2025, exploring the factors shaping the landscape, the implications for diverse sectors, and the potential breakthroughs on the horizon.

Factors Driving Melting Point Trends

Several factors are driving the evolution of melting point trends in materials science:

- Advancements in Computational Modeling: Sophisticated computational tools are enabling researchers to predict and design materials with specific melting point properties. These models can simulate atomic interactions and predict material behavior under various conditions, accelerating the discovery and development of novel materials.

- Nanotechnology and Materials Engineering: Nanotechnology offers the ability to manipulate materials at the nanoscale, creating structures with unique properties. By controlling the size and shape of nanomaterials, scientists can precisely engineer their melting points, leading to materials with tailored thermal properties.

- High-Throughput Screening and Artificial Intelligence: High-throughput screening techniques allow for the rapid testing and evaluation of numerous materials, identifying promising candidates with desired melting point characteristics. Integrating artificial intelligence (AI) algorithms into material discovery processes further enhances efficiency, allowing for the identification of optimal material compositions based on specific melting point requirements.

- Demand for High-Performance Materials: Industries are constantly seeking materials with enhanced properties, including high melting points, to withstand extreme temperatures and harsh environments. This demand drives research efforts to develop materials with improved thermal stability, crucial for applications in aerospace, energy generation, and electronics.

Impact of Melting Point Trends on Various Industries

The evolving melting point trends have significant implications for various industries:

- Aerospace: The aerospace industry demands materials that can withstand extreme temperatures during flight and re-entry. High-melting point alloys, ceramics, and composites are crucial for building lightweight and durable aircraft components, contributing to fuel efficiency and safety.

- Energy Generation: The development of new materials with high melting points is vital for improving energy efficiency and safety in power generation. For instance, high-temperature superconductors with elevated melting points could enable the development of more efficient and compact power grids.

- Electronics: The miniaturization of electronic devices requires materials with high melting points to withstand the heat generated during operation. High-temperature polymers and ceramics are essential for creating reliable and durable components in smartphones, computers, and other electronics.

- Manufacturing: High-melting point materials are crucial for various manufacturing processes, including metal casting, welding, and forging. Understanding the melting point behavior of different materials allows for optimized manufacturing processes, improving product quality and reducing production costs.

Potential Breakthroughs in Melting Point Research

The future of melting point trends holds exciting possibilities for groundbreaking advancements:

- Development of High-Entropy Alloys: High-entropy alloys are a new class of materials with exceptional properties, including high melting points and enhanced strength. These alloys are composed of multiple elements in near-equimolar ratios, leading to unique microstructures and improved performance.

- Discovery of Novel Ceramics with Tailored Melting Points: Advancements in ceramic synthesis techniques allow for the creation of ceramics with tailored melting points, enabling their use in high-temperature applications like turbine blades and nuclear reactors.

- Integration of Artificial Intelligence for Material Design: AI algorithms are increasingly being used to predict and design materials with specific melting points, accelerating the discovery of new materials with desired properties.

- Development of Materials with Tunable Melting Points: Researchers are exploring materials with tunable melting points, allowing for dynamic control of their properties based on environmental conditions. These materials could find applications in self-healing materials, shape-memory alloys, and responsive devices.

Related Searches

The evolving melting point trends have spurred interest in various related areas:

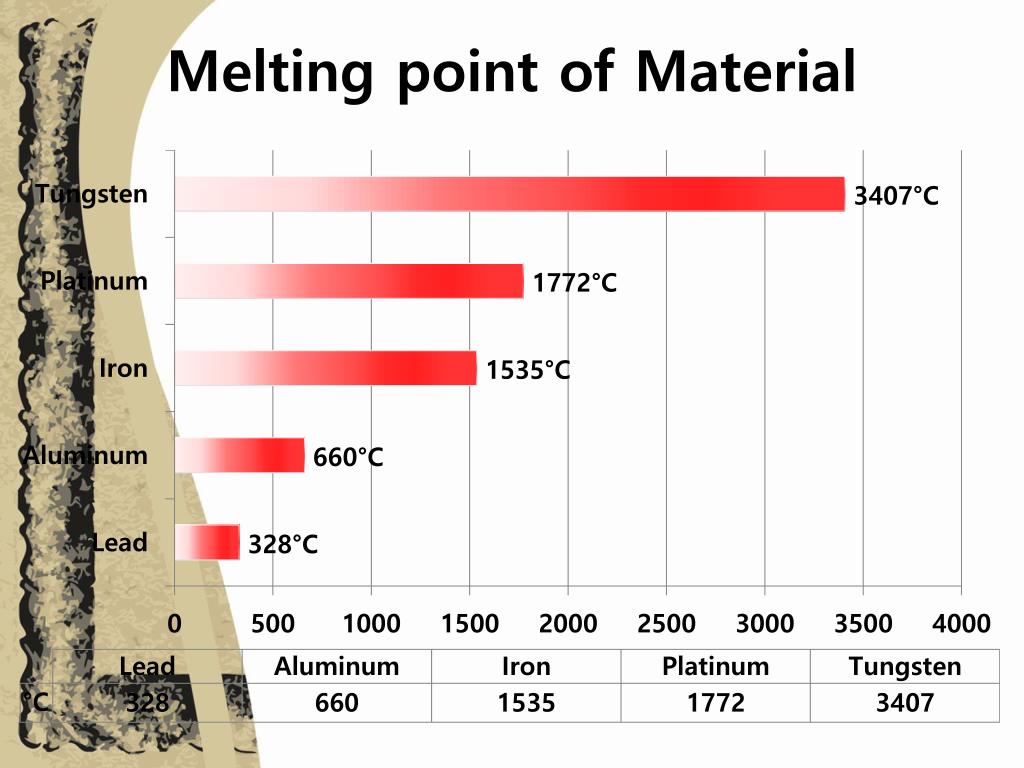

- Melting Point of Metals: Understanding the melting points of different metals is crucial for various applications, from metal casting to welding. Research focuses on developing new alloys with higher melting points and improved properties.

- Melting Point of Polymers: Polymers are essential in various industries, and their melting points influence their processing and applications. Research investigates the relationship between polymer structure and melting point, leading to the development of high-performance polymers with tailored thermal properties.

- Melting Point of Ceramics: Ceramics are known for their high melting points and resistance to extreme temperatures. Research focuses on developing new ceramics with tailored melting points for applications in aerospace, energy generation, and electronics.

- Melting Point of Composites: Composites are materials composed of two or more distinct components, often with different melting points. Understanding the melting behavior of composites is essential for optimizing their processing and performance.

- Melting Point Measurement Techniques: Accurate measurement of melting points is essential for material characterization and quality control. Various techniques are employed, including differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), and optical microscopy.

- Melting Point Depression: The addition of impurities can lower the melting point of a substance. This phenomenon, known as melting point depression, is used in various applications, including cryoscopic determination of molecular weight and freezing point depression of antifreeze solutions.

- Melting Point Elevation: The addition of certain substances can increase the melting point of a material. This phenomenon, known as melting point elevation, is used in various applications, including the development of high-temperature alloys and the synthesis of high-melting point ceramics.

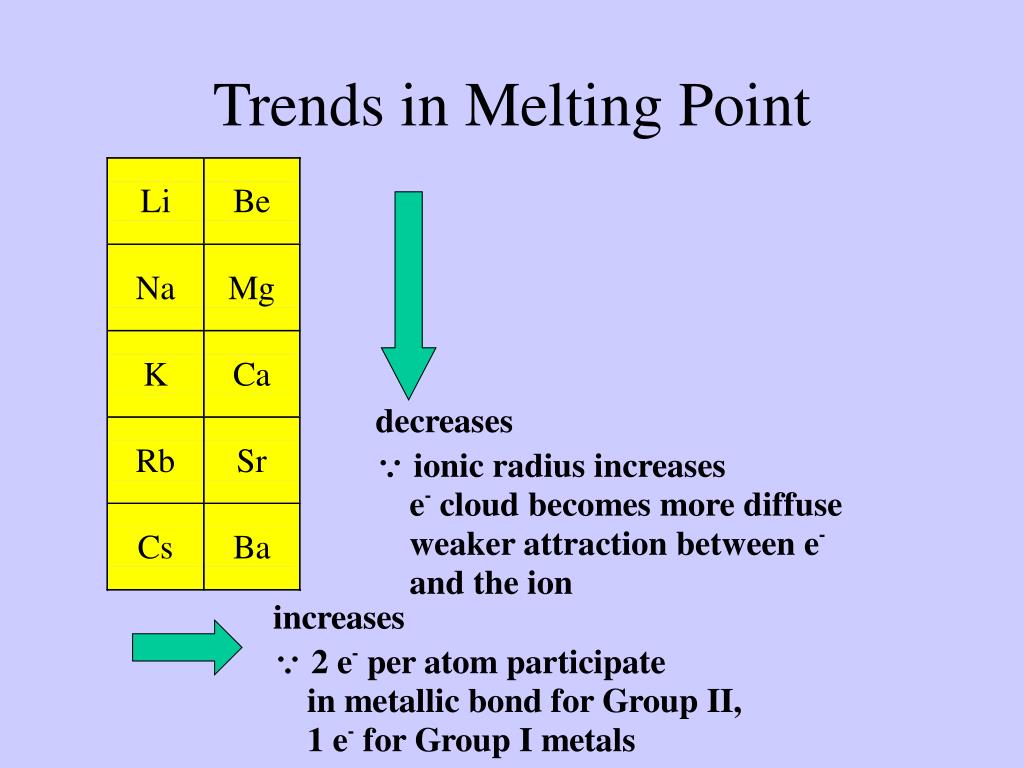

- Melting Point and Crystalline Structure: The melting point of a material is influenced by its crystalline structure. Understanding the relationship between crystal structure and melting point is crucial for predicting the behavior of materials under different conditions.

FAQs

What is the importance of melting point in materials science?

The melting point is a fundamental property of materials, determining their behavior at elevated temperatures. It influences a material’s suitability for various applications, including its use in high-temperature environments, its processing techniques, and its stability under different conditions.

What are the factors that influence the melting point of a material?

The melting point of a material is influenced by several factors, including:

- Intermolecular forces: Stronger intermolecular forces lead to higher melting points.

- Molecular weight: Higher molecular weights generally result in higher melting points.

- Crystal structure: Materials with more ordered crystal structures tend to have higher melting points.

- Impurities: The presence of impurities can lower the melting point of a substance.

How are melting point trends expected to impact the electronics industry?

The electronics industry relies on materials with high melting points to withstand the heat generated during device operation. The development of new materials with even higher melting points will enable the creation of more powerful and compact electronic devices.

What are the potential challenges in developing materials with higher melting points?

Developing materials with higher melting points often presents challenges, including:

- Cost and availability of raw materials: Some high-melting point materials are rare and expensive.

- Processing difficulties: Processing high-melting point materials can be challenging due to their high melting temperatures and potential reactivity.

- Performance limitations: High-melting point materials may exhibit other limitations, such as low ductility or poor machinability.

How can AI be used to advance melting point research?

AI algorithms can be used to:

- Predict the melting points of new materials: AI models can analyze vast datasets of material properties and predict the melting points of novel materials.

- Optimize material design: AI can assist in designing materials with specific melting points by identifying optimal compositions and structures.

- Accelerate material discovery: AI can automate the screening and evaluation of numerous materials, identifying promising candidates with desired melting point characteristics.

Tips for Understanding Melting Point Trends

- Stay informed about advancements in materials science: Follow industry publications, attend conferences, and engage with research groups to stay abreast of the latest developments in melting point research.

- Explore the applications of high-melting point materials: Understand the role of melting point in various industries, including aerospace, energy generation, and electronics.

- Consider the environmental impact of materials development: Evaluate the sustainability of materials development and explore the use of environmentally friendly materials with high melting points.

Conclusion

The melting point trends in 2025 represent a dynamic landscape driven by advancements in computational modeling, nanotechnology, high-throughput screening, and artificial intelligence. These trends are shaping the future of materials science, leading to the development of novel materials with tailored thermal properties and improved performance. As we move forward, understanding the factors influencing melting point behavior and the potential breakthroughs on the horizon will be crucial for industries seeking to leverage the power of materials science to address global challenges and drive innovation.

Closure

Thus, we hope this article has provided valuable insights into Melting Point Trends 2025: A Comprehensive Look at the Future of Materials Science. We hope you find this article informative and beneficial. See you in our next article!